How V-VAC helped a food manufacturer eliminate spoilage through real-time cold storage monitoring, achieving 90% waste reduction and improved product quality.

The Challenge

In the food manufacturing industry, temperature precision defines quality. For products like bread, even the smallest deviation in yeast storage temperature can result in spoilage, inconsistency, or halted production. At one food manufacturing facility, maintaining yeast at its required 3°C to 5°C range became an ongoing struggle. Unmonitored door openings, compressor malfunctions, and a lack of automated alerts created unpredictable storage conditions. Each temperature fluctuation meant potential product loss, delayed schedules, and additional production costs.

Our Solution

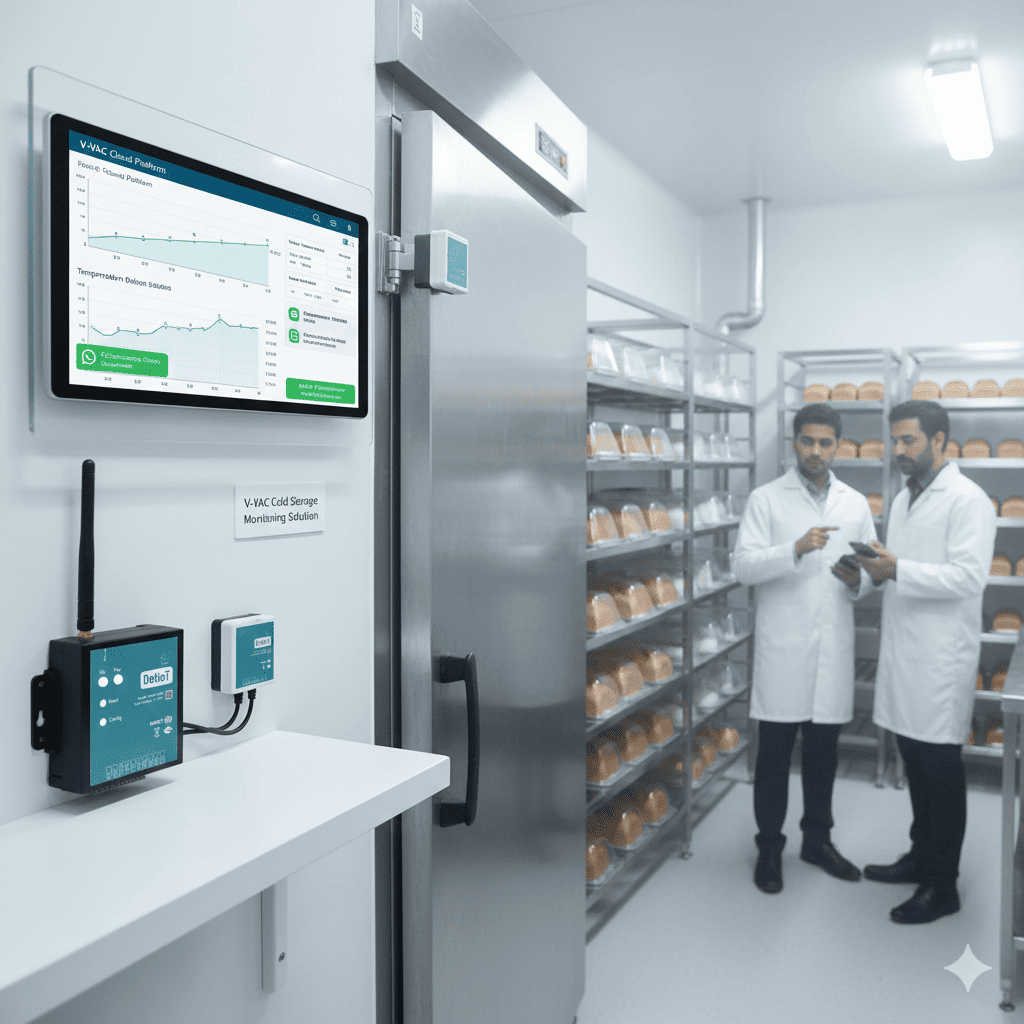

To address these challenges, Volkkommen Industries deployed the V-VAC Cold Storage Monitoring Solution — a smart, IoT-enabled system built to ensure precision, control, and reliability in temperature-sensitive environments. This implementation combined advanced IoT devices with real-time analytics through the V-VAC platform. Key Components Implemented: DeltaT – Temperature Monitoring Device, Zyphion – Equipment Status Monitoring Device, Zyphion – Door Status Monitoring. All devices communicate directly with the V-VAC Cloud Platform, where live data from sensors is processed, displayed, and analyzed.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

The results were immediate and measurable. After implementing the V-VAC Cold Storage Monitoring Solution, the facility achieved significant improvements: Reduced Spoilage and Waste - Accurate, 24/7 temperature monitoring eliminated losses from raw material spoilage and ensured stable yeast quality. Enhanced Product Consistency - Stable storage conditions directly improved bread texture, taste, and consistency, reinforcing customer satisfaction. Real-Time Alerts and Rapid Response - Instant notifications via WhatsApp, email, and dashboard allowed swift corrective actions, reducing downtime and ensuring uninterrupted production.