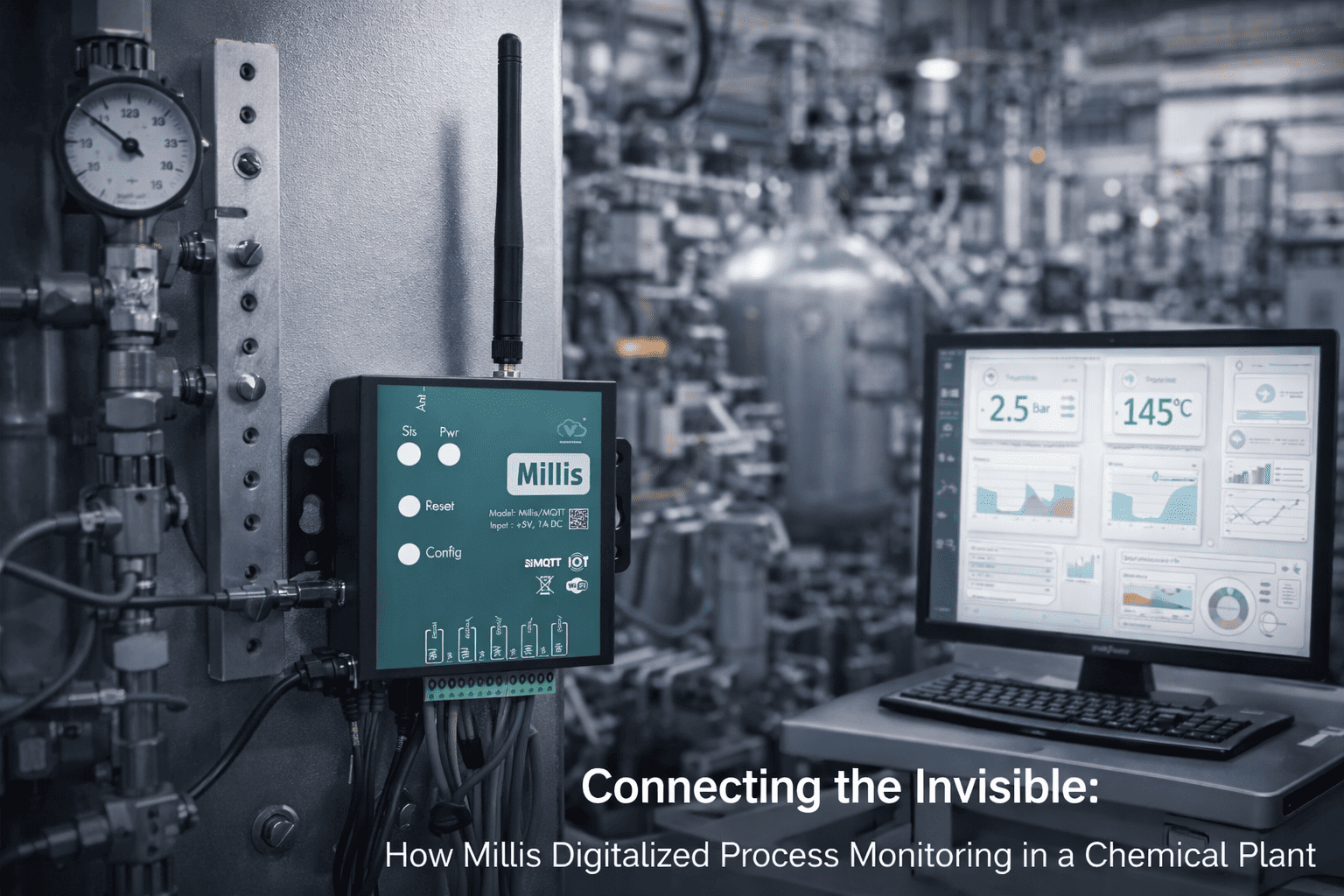

In a large chemical plant, critical sensor data was trapped in analog signals. To turn this invisible intelligence into actionable decisions, the facility bridged its legacy systems to a digital future with Volkkommen's Millis.

The Challenge

The Challenge: Data Gaps in Critical Process Lines The plant's core operations depended on multiple reactors, boilers, and cooling systems.Each was equipped with 4–20 mA and 0–10 V transmitters, but readings were only available locally through gauges or control panels.Engineers relied on manual logging to track changes, leaving long intervals where key process variations went unnoticed. Sudden pressure drops or temperature spikes were often detected after they affected product quality or safety.The goal was clear — bring every analog signal into the digital domain for real-time monitoring, analysis, and control.

Our Solution

The Turning Point: Integrating Millis Volkkommen Industries introduced Millis, a compact, low-power IoT data acquisition device capable of interfacing with any sensor or actuator using 4–20 mA, 0–10 V, or digital input.Its deployment required no redesign — Millis connected directly to existing transmitter loops and began transmitting live data over Wi-Fi and LoRa networks to the plant's V-VAC cloud platform. From flow meters on chemical feed lines to temperature probes in reaction vessels, every reading was now visible in real time.Operators could view dashboards, set thresholds, and receive instant alerts the moment parameters exceeded safe limits. Inside Millis: Turning Analog Into Intelligence Millis continuously sampled input signals, converting them into secure MQTT data streams for the cloud.Each unit offered: Analog & digital input channels for multiple sensors Relay outputs for automated control actions Selectable polling intervals for optimizing data frequency Threshold-based alerts triggered at defined set points By combining this flexibility with LoRa's long-range coverage, the plant gained complete visibility across distant equipment, including outdoor pumping stations and chemical storage zones — without running new communication cables. From Data to Action With Millis online, engineers could now: Track real-time flow and temperature trends across every process. Correlate readings from different transmitters to detect process drift. Remotely switch equipment using Millis's built-in relay when alerts were triggered. Generate time-stamped reports for compliance and performance audits. Even minor deviations in feed-pump pressure or cooling water flow were identified early, preventing process imbalance and reducing maintenance costs.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

The Results: A Smarter, Connected Plant

Within months, the transformation was evident:

100 % visibility of analog sensor data through dashboards.

Reduced manual inspection time by 60 %.

Improved process reliability and energy efficiency.

Condition-based control, reducing wear on valves and pumps.

Centralized analytics for process optimization and safety assurance.

The plant had effectively turned every transmitter into a digital sensor — all through Millis.

The Impact: From Monitoring to Mastery

Millis didn't just connect sensors — it connected people, machines, and insights.Engineers no longer waited for reports; they saw process health live.Supervisors analyzed weeks of data in seconds. And management could make confident, data-driven decisions backed by real-time visibility.

Today, the plant is expanding its Millis network to monitor boilers, chillers, and conveyor systems, creating a unified digital ecosystem powered by IoT.

At Volkkommen Industries, this success story demonstrates how Millis transforms ordinary analog signals into extraordinary operational intelligence — proving that the future of industrial monitoring can begin with the sensors you already have.