A leading manufacturing facility struggled with rising energy costs and poor resource efficiency. Lacking real-time insight into energy use and equipment performance,

The Challenge

Challenges Identified Before implementation, the facility's operations were largely manual and disconnected, leading to: Unmonitored equipment running beyond scheduled hours. High energy wastage from pumps, motors, and HVAC systems. Lack of visibility into process-level consumption. Inconsistent reporting and delayed decision-making. Escalating energy bills without clear insights into root causes. The organization needed a centralized, intelligent system that could transform raw energy data into actionable insights and enable immediate corrective actions.

Our Solution

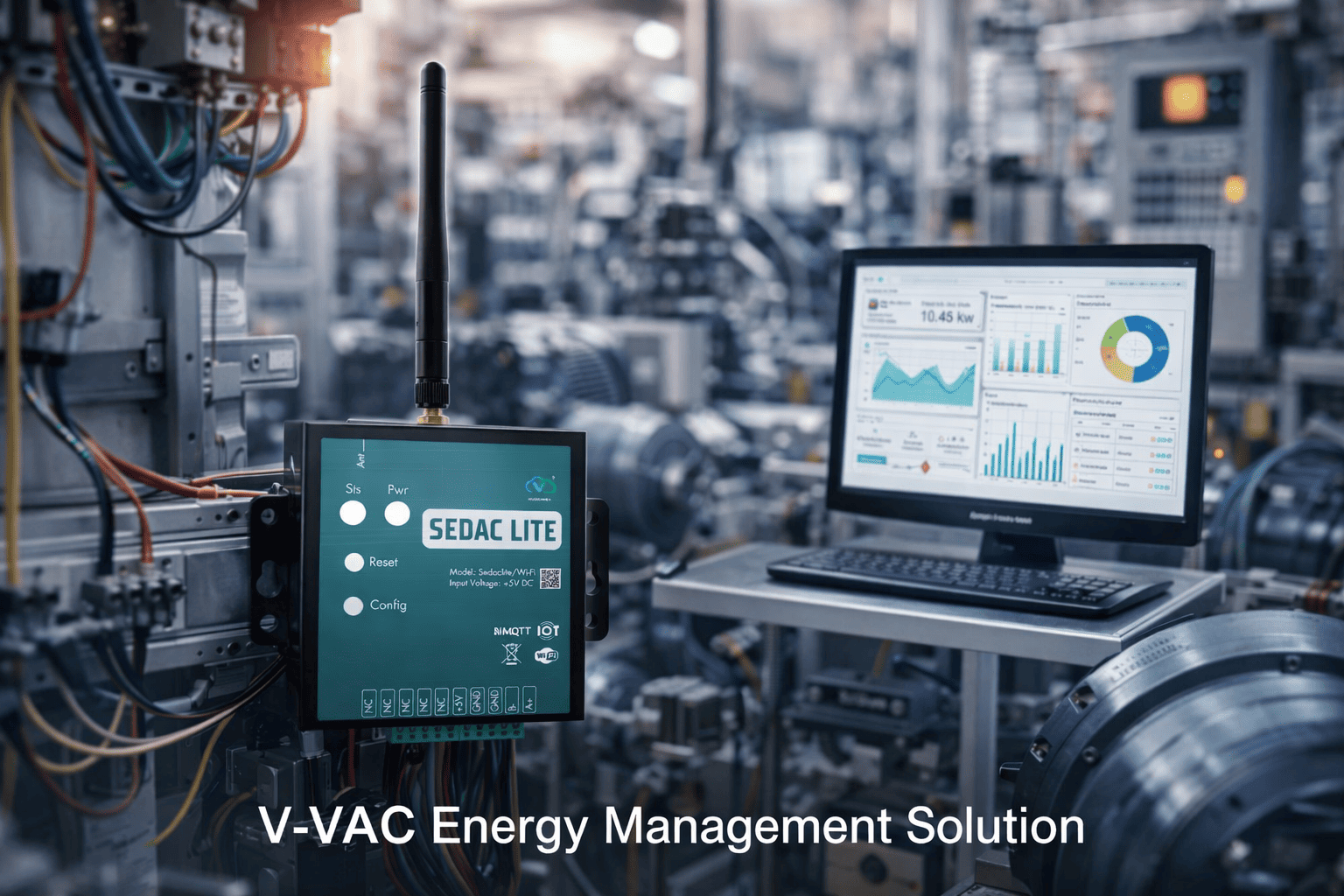

The Solution: Smart Energy Optimization with V-VAC To overcome these challenges, Volkkommen Industries implemented the V-VAC Energy Management Solution, built to integrate seamlessly with existing infrastructure and deliver precise, real-time control. Key Components of the Solution Smart MeteringAdvanced digital energy meters were installed across all major load points to measure consumption in real time.This provided granular visibility into system-level and equipment-level energy usage. Analytics DashboardThe intuitive V-VAC dashboard offered facility managers live data visualization, trend analysis, and actionable reports — all accessible remotely via cloud or mobile. Automated Energy ControlsIntelligent algorithms and automation features optimized power distribution, adjusted loads, and controlled equipment operation dynamically based on demand. Implementation Process 1. Initial AssessmentA detailed energy audit was conducted to identify inefficiencies, high-consumption areas, and improvement opportunities. 2. System IntegrationSmart meters and IoT sensors were networked across key points of the facility — including motors, compressors, and lighting systems — creating a unified monitoring environment. 3. Data Analysis & Actionable InsightsReal-time energy data was analyzed to detect usage spikes, idle equipment, and process inefficiencies.Automated alerts were configured to inform the maintenance team about anomalies or excessive consumption. This integration provided the foundation for automated optimization and strategic energy management — transforming data into daily operational value.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

The Results: Data-Driven Efficiency in Action

The impact of the V-VAC Energy Management Solution was immediate and measurable within the first year of deployment.

1. Energy Reduction Achieved

Energy consumption across monitored sections dropped by over 20%, attributed to improved load management and elimination of unnecessary runtime.

2. Cost Savings Realized

Reduced energy waste led to significant cost reductions, directly improving the facility's financial performance and return on investment.

3. Sustainability and Compliance

Lower energy use resulted in a notable decrease in carbon emissions, aligning the facility with sustainability initiatives and regulatory targets.

4. Improved Operational Efficiency

Centralized monitoring and automated alerts simplified daily management, reduced manual interventions, and enhanced system reliability.

Empowering Smarter Energy Management

Beyond savings, the V-VAC solution provided a powerful shift in how the organization approached energy management.For the first time, teams had real-time visibility into where, when, and how energy was being consumed — empowering them to make informed, proactive decisions.

Testimonial

"The implementation of the V-VAC Energy Management Solution transformed our approach to energy management, making our operations not only more efficient but also more sustainable."— Facility Manager

Long-Term Impact and Future Roadmap

The successful deployment has inspired the organization to further expand the system's capabilities.Plans are already in motion to:

Integrate predictive analytics for advanced anomaly detection and failure prediction.

Extend V-VAC monitoring to additional plants and processes.

Incorporate AI-based optimization models for load balancing and energy forecasting.

This continuous evolution ensures that the facility remains a leader in energy efficiency, operational excellence, and environmental responsibility.

Key Highlights

✅ 20%+ reduction in energy consumption within the first year.✅ Significant operational cost savings through real-time insights and automation.✅ Enhanced transparency across systems and departments.✅ Improved sustainability metrics with reduced carbon footprint.✅ Scalable and adaptable architecture for multi-facility deployment.

Conclusion

The V-VAC Energy Management Solution proved instrumental in driving measurable energy savings and advancing sustainability goals.By combining smart metering, real-time analytics, and automated control, Volkkommen Industries delivered a solution that not only met but exceeded the client's efficiency targets.

This case study stands as a testament to how V-VAC transforms industrial facilities into intelligent, energy-optimized ecosystems — paving the way toward a smarter, greener future.

V-VAC by Volkkommen Industries — empowering industries with intelligent energy visibility, control, and efficiency.