How V-VAC helped a bed manufacturer eliminate production inconsistencies through DeltaT temperature monitoring, achieving improved material curing and consistent product quality.

The Challenge

In their production line, processes like foam curing, adhesive bonding, and material coating relied heavily on stable temperature conditions. Yet, fluctuations often went unnoticed. Manual temperature checks provided delayed and inconsistent readings, leading to uneven foam density, bonding issues, and unplanned rework. What the team needed was a smarter way — a system that could see what humans couldn't, respond faster than manual checks, and ensure that every batch left the line with uniform quality.

Our Solution

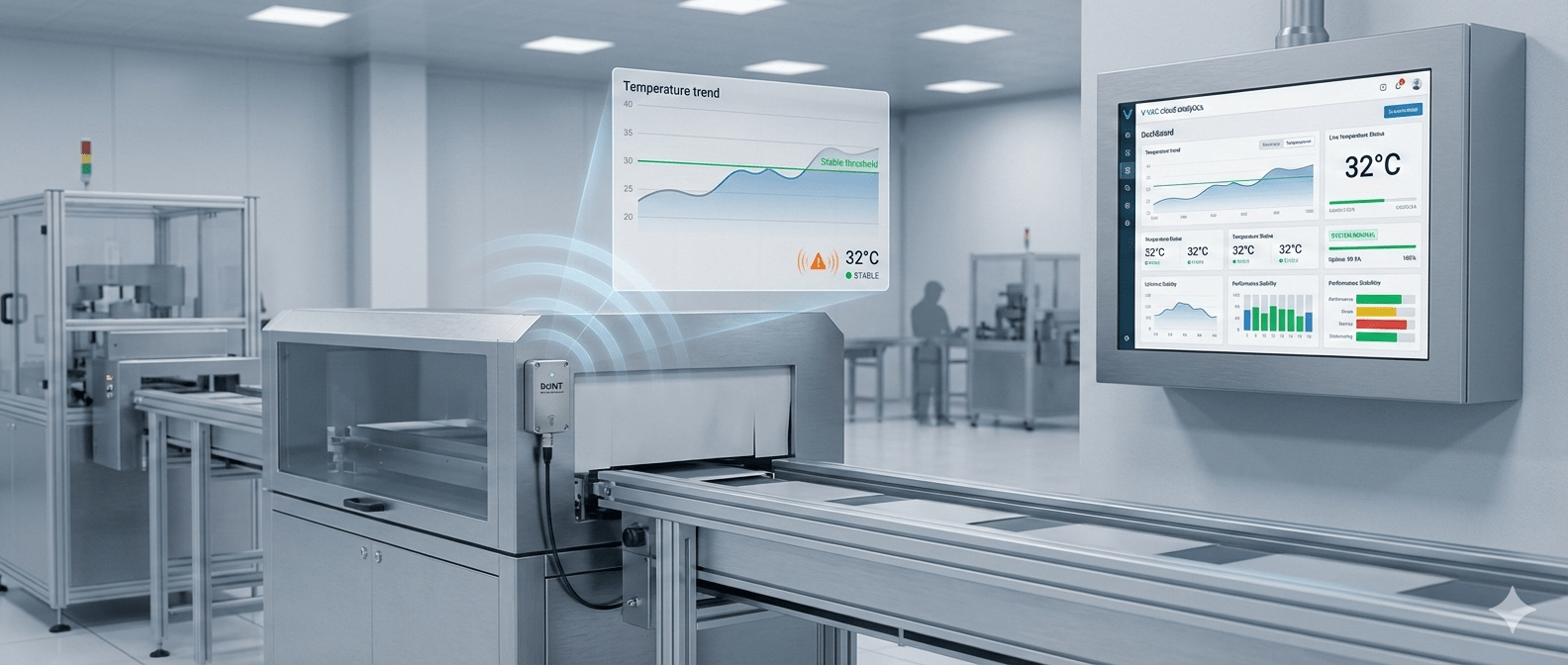

Enter DeltaT, Volkkommen Industries' IoT-based temperature monitoring device. Compact, precise, and intelligent, DeltaT was installed near key production stages where temperature stability was most critical. Through continuous real-time monitoring, DeltaT delivered accurate readings directly to a V-VAC cloud dashboard, allowing supervisors to visualize live data, set threshold limits, and receive instant alerts if conditions deviated. For the first time, the factory floor had a digital eye constantly watching over the production environment — ensuring that heat levels stayed within the perfect range for material curing and bonding.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

Within weeks, the change was visible: Temperature stability improved, eliminating material defects. Alerts and notifications helped technicians act before problems escalated. Reduced rework and waste, saving both time and cost. Consistent product quality, ensuring every bed met brand standards. DeltaT transformed how the company viewed process control. What began as a simple need for temperature accuracy evolved into a journey toward IoT-enabled manufacturing intelligence.