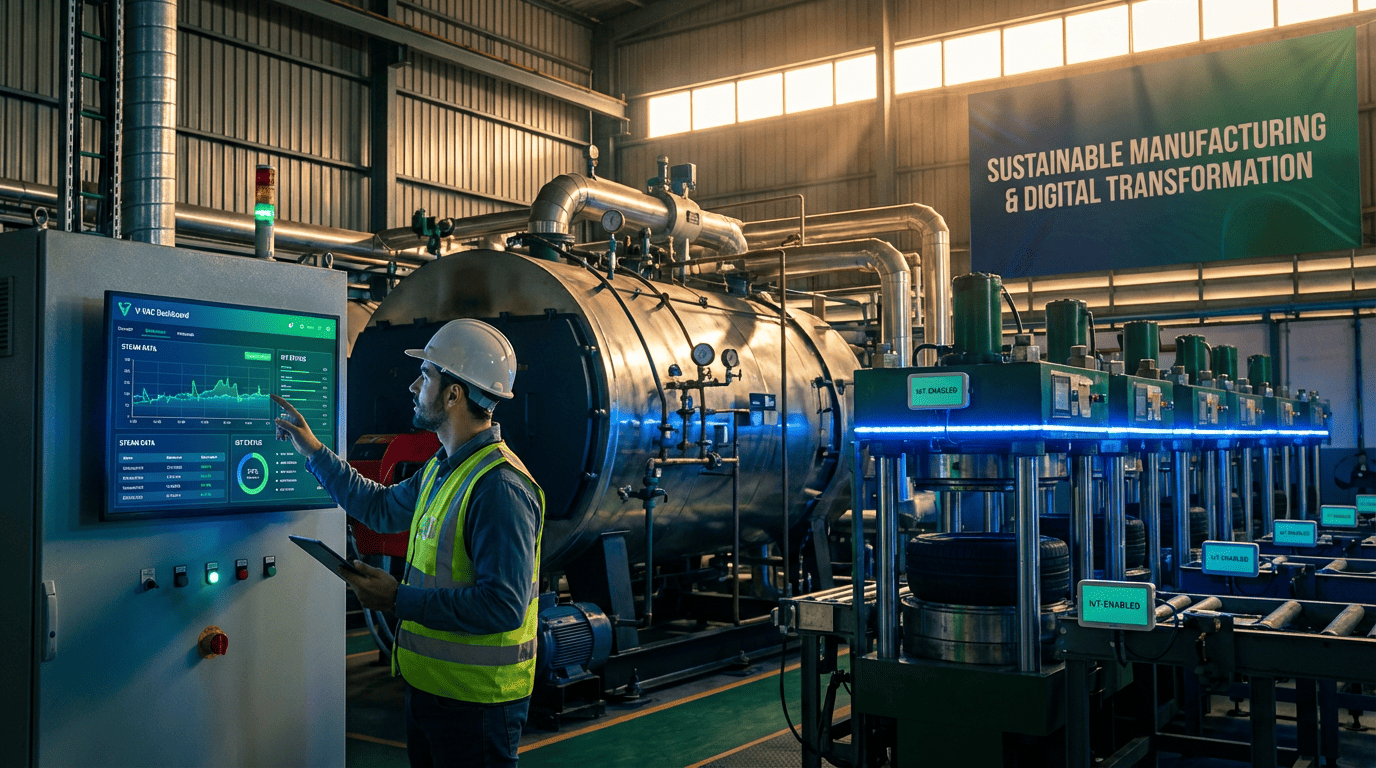

How V-VAC IoT-based Steam and Boiler Monitoring Solution optimized steam consumption across 69 curing presses, achieving 10-20% reduction in energy usage and improved boiler efficiency.

The Challenge

Background: Steam — The Heart of Tyre Manufacturing In tyre manufacturing, steam is one of the most critical utilities, powering curing presses that operate continuously across multiple shifts. Efficient management of steam usage is vital for maintaining product quality, reducing energy consumption, and minimizing production costs. At a leading tyre manufacturing facility, steam for 69 curing presses was generated by a large 18 t/h industrial boiler. However, without a proper monitoring and control system, steam consumption varied unpredictably — resulting in energy losses, operational inefficiencies, and unnecessary strain on the boiler. The facility partnered with Volkkommen Industries to deploy the V-VAC IoT-based Steam and Boiler Monitoring Solution, aiming to bring data-driven precision to steam consumption and optimize boiler performance for improved productivity and energy efficiency. Challenges Before adopting the V-VAC solution, the facility faced several key issues: No visibility into individual curing press steam usage or running status Uncontrolled addition of high-consumption presses, causing pressure fluctuations and boiler stress Frequent press shutdowns required reheating, restarting the steam cycle from scratch — increasing energy use Inconsistent coordination between operators and maintenance teams Increased fuel consumption due to poor load balancing and lack of predictive analytics The absence of real-time data and control mechanisms led to excessive steam wastage, reduced boiler efficiency, and higher operating costs.

Our Solution

The Solution: IoT-Driven Steam & Boiler Optimization with V-VAC Volkkommen Industries implemented the V-VAC IoT Solution, designed to monitor, analyze, and control steam usage in real time. The system was integrated with Programmable Logic Controllers (PLCs) to collect continuous operational data from all 69 curing presses and the central boiler. This integration enabled: Real-time visibility of each press's steam consumption Automated control of curing press operation based on consumption thresholds Predictive analytics to maintain optimal boiler load and reduce wastage Implementation Highlights 1. Real-Time Monitoring & Target-Based Control Using IoT-enabled connectivity, V-VAC continuously tracked the steam flow, pressure, and temperature of each curing press. A SKU-based database was configured to set steam consumption thresholds per press type. The platform compared real-time usage against these targets and alerted operators if any press exceeded its preset pattern. This closed-loop control mechanism allowed the maintenance team to maintain steady steam demand across shifts, reducing unnecessary load fluctuations on the boiler. 2. Intelligent Data Analysis through the V-VAC Dashboard The V-VAC dashboard served as the central monitoring interface for plant engineers. It displayed: Real-time steam consumption of all curing presses Comparison between actual and targeted usage Graphical and tabular reports for performance analysis Critical alarms and notifications for deviation or abnormal operation Individual alarm pages were also included, allowing teams to configure custom alerts for equipment anomalies or excessive consumption. This improved situational awareness and allowed teams to respond promptly, maintaining stable production and efficient boiler performance. 3. Boiler Efficiency Optimization V-VAC's analytics module monitored boiler parameters such as pressure, temperature, and fuel efficiency. By correlating steam demand with energy usage, the system provided insights to maintain optimal boiler load and combustion efficiency. This helped reduce fuel wastage and supported preventive maintenance by identifying early signs of inefficiency or imbalance. 4. Predictive Maintenance & Continuous Improvement With continuous data collection, V-VAC enabled maintenance teams to analyze long-term trends, detect irregularities, and plan maintenance activities more effectively. Patterns in steam demand and boiler performance were studied to prevent unplanned downtimes and improve operational consistency. The platform's data-driven approach encouraged ongoing process optimization across shifts and production batches.

Key Results

The implementation delivered measurable improvements across operations, efficiency, and cost reduction:

The Results: Measurable Gains in Efficiency and Reliability

After implementing V-VAC, the tyre manufacturing facility experienced a significant improvement in steam management and boiler performance.

1. Controlled Steam Consumption

Steam consumption across curing presses was optimized through threshold-based control, ensuring only the required quantity was used per process.

2. Improved Boiler Efficiency

By maintaining a balanced and predictable steam load, the boiler operated more efficiently with lower fuel usage and fewer restarts.

3. Reduced Energy Costs

With stable load management and reduced wastage, the facility recorded energy cost savings of 5%–15% within the first monitoring cycle.

4. Better Maintenance Planning

Real-time data and predictive alerts enabled proactive maintenance scheduling, reducing unexpected shutdowns and extending equipment life.

5. Enhanced Productivity

Consistent steam availability ensured uninterrupted curing operations, contributing to higher productivity and process stability.

Key Benefits of Implementing V-VAC

10%–20% reduction in steam consumption, minimizing energy losses

5%–15% savings in energy costs through optimized operation and load balancing

15%–20% improvement in maintenance efficiency with early fault detection

5%–10% increase in overall productivity from consistent steam availability

10%–20% reduction in process waste by avoiding overconsumption and unplanned restarts

Data-driven decision-making through continuous monitoring and smart analytics

A Step Toward Smarter, Sustainable Manufacturing

The integration of V-VAC IoT technology transformed how the tyre manufacturing facility managed its most critical utilities — steam and boiler performance. By digitizing consumption data, introducing predictive insights, and automating control, Volkkommen Industries helped the facility achieve operational discipline, cost savings, and improved sustainability.

Today, the plant operates with higher energy efficiency, better resource management, and full visibility into its utility performance — setting a new benchmark for smart manufacturing in the tyre industry.

V-VAC by Volkkommen Industries — empowering industries with data-driven efficiency and sustainable operations.