Comprehensive environmental monitoring for clean rooms ensuring compliance with ISO standards through continuous tracking of particles, temperature, humidity, and pressure.

Clean Room Monitoring Solution provides continuous environmental monitoring to ensure clean room compliance with ISO 14644 and other regulatory standards, protecting product quality and meeting validation requirements.

Clean rooms require strict environmental control. Manual monitoring is insufficient for 24/7 compliance, audit trails are difficult to maintain, and deviations can compromise product quality and regulatory status.

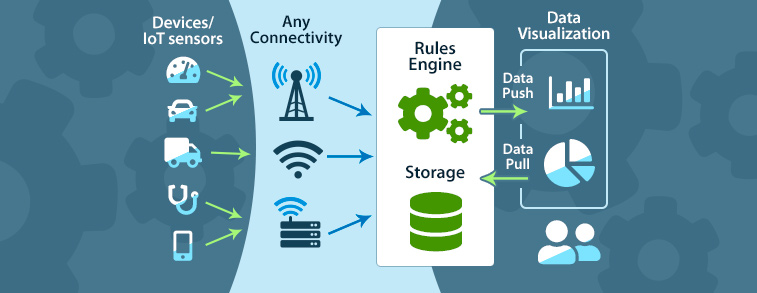

An automated monitoring system that continuously tracks all critical parameters, maintains comprehensive audit trails, provides instant alerts, and generates compliance-ready reports.

Step-by-step process of our solution implementation

Sensor Network: Deploy particle counters and environmental sensors at critical locations

Continuous Monitoring: Track particles, temperature, humidity, pressure differential, and air velocity

Data Logging: Securely store all measurements with timestamps for audit trails

Alert Management: Instant notifications for any parameter excursions

Compliance Reporting: Automated generation of validation and audit reports

Ensure regulatory compliance (FDA, EU GMP, WHO)

Protect product quality and patient safety

24/7 automated monitoring

Eliminate manual recording errors

Instant deviation alerts

Audit-ready documentation

Reduce validation time and costs

Support continuous process verification

Enable remote monitoring and control

Pharmaceutical manufacturing and packaging

Sterile compounding facilities

Semiconductor fabrication

Biotechnology laboratories

Medical device manufacturing

Hospital operating rooms and isolation rooms

Aerospace component manufacturing

Food and beverage aseptic processing

Transform your operations with Clean Room. Contact us today for a personalized consultation and demo.