Predictive maintenance solution using vibration analysis, temperature monitoring, and AI to detect machine faults early and prevent unexpected breakdowns.

Machine Health Monitoring Solution uses advanced sensors and AI analytics to continuously monitor machine condition, predict failures before they occur, and optimize maintenance schedules.

Unexpected machine breakdowns cause production losses, emergency repair costs, and safety hazards. Traditional time-based maintenance is inefficient and often misses developing faults.

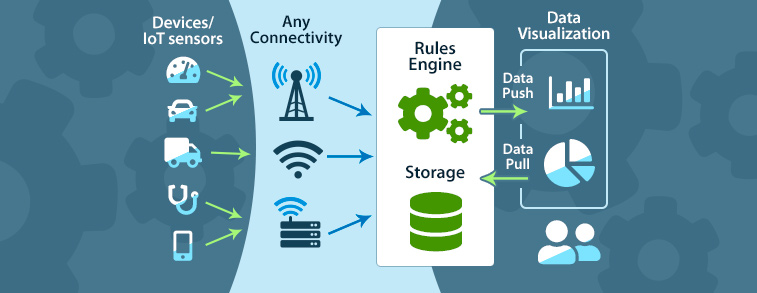

A predictive maintenance system that continuously monitors machine health indicators, uses AI to detect anomalies and predict failures, and provides actionable maintenance recommendations.

Step-by-step process of our solution implementation

Sensor Deployment: Install vibration, temperature, and current sensors on critical equipment

Continuous Monitoring: Collect high-frequency data on machine health parameters

AI Analysis: Machine learning algorithms detect patterns and anomalies

Fault Detection: Early identification of bearing wear, misalignment, imbalance, and other issues

Maintenance Planning: Predictive alerts and recommendations for optimal maintenance timing

Reduce unplanned downtime by 30-50%

Lower maintenance costs by 20-40%

Extend machine lifespan by 20-30%

Improve safety by preventing catastrophic failures

Optimize spare parts inventory

Enable condition-based maintenance

Increase overall equipment effectiveness (OEE)

Support ISO 55000 asset management

Remote expert diagnostics

Manufacturing production lines

Rotating equipment (pumps, motors, compressors)

Conveyor systems

CNC machines and machining centers

Wind turbines

HVAC equipment

Mining crushers and mills

Paper mill machinery

Food processing equipment

Transform your operations with Machine Health. Contact us today for a personalized consultation and demo.