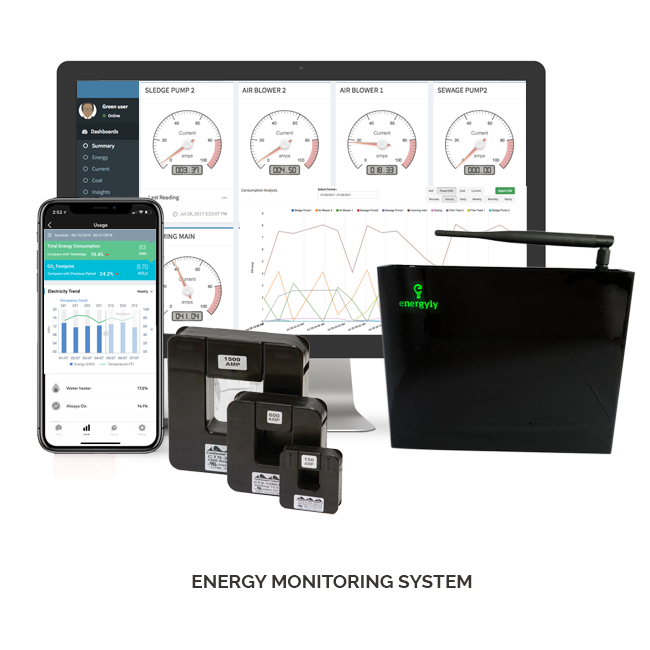

Comprehensive pump monitoring system tracking performance, energy consumption, and health to optimize operation, prevent failures, and reduce costs.

Pump Monitoring & Control Solution provides real-time visibility into pump performance, enabling optimization, predictive maintenance, and energy savings through intelligent monitoring and control.

Pumps consume 20-25% of industrial energy. Inefficient operation, cavitation, dry running, and unexpected failures lead to high costs, downtime, and equipment damage.

An intelligent monitoring system that tracks pump performance parameters, detects anomalies, prevents failures, optimizes operation, and enables predictive maintenance.

Step-by-step process of our solution implementation

Sensor Integration: Connect pressure, flow, vibration, and current sensors to pumps

Performance Monitoring: Track flow rate, pressure, power consumption, and efficiency

Health Analysis: Monitor vibration, bearing temperature, and seal leakage

Control Optimization: Automated VFD control for optimal efficiency

Predictive Maintenance: Early detection of cavitation, bearing wear, and seal failures

Reduce energy consumption by 20-30%

Prevent pump failures and damage

Extend pump and seal lifespan

Minimize unplanned downtime

Optimize pump selection and staging

Detect leaks and inefficiencies

Improve process control

Lower maintenance costs

Enable remote operation and troubleshooting

Water and wastewater treatment plants

HVAC chilled water systems

Chemical and process industries

Agricultural irrigation systems

Building water supply systems

Oil and gas pipeline pumps

Mining dewatering pumps

Food and beverage processing

Power plant cooling water pumps

Transform your operations with Pump Monitoring. Contact us today for a personalized consultation and demo.